charpy impact test lab manual|charpy impact test calculations : importing In charpy test, the specimen is placed as ‘cantilever beam’. The specimens have V-shaped notch of 45°. U-shaped notch is also common. The notch is located on tension side . WEBClube fonte são paulo O CFSP oferece duas categorias de associação e para ambas a concretização é feita diretamente na secretaria. Secretaria preencha o formulário e em breve retornaremos seu contato Rua José Paulino, nº 2138Vila Itapura – Campinas – SP. Rua Amandio Augusto Malheiros Lopes – s/nºLoteamento Village – Campinas – SP. .

{plog:ftitle_list}

Cosplayer, geek, gamer. You can find 18+ content here: https://ladymelamori.carrd.co

Microsoft Word - Lab Manual 2008. Charpy Impact Test. Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy .

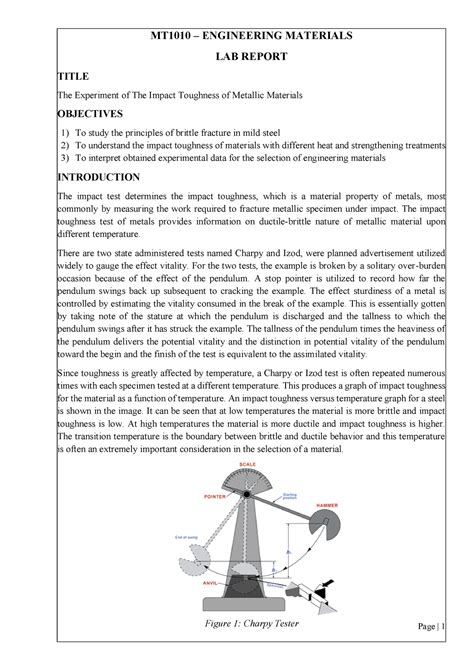

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .

C scale is commonly used for testing the hardness of alloy cast irons. In Rockwell hardness testing, the minor load for all cases is 10 Kg. whereas major loads for scales C and B are 150 .

In charpy test, the specimen is placed as ‘cantilever beam’. The specimens have V-shaped notch of 45°. U-shaped notch is also common. The notch is located on tension side .

To determine experimental data for spring testing machine, compression testing machine, impact tester, hardness tester. To determine stress analysis and design of beams subjected .

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .OBJECT: To determine the impact strength of steel by Charpy test APPARATUS: 1. Impact testing machine 2. A steel specimen 10 mm X 10mm X 55mm THEORY: An impact test .TITLE: IMPACT TEST AIM: To determine the Impact toughness (strain energy) through Izod test and Charpy test THEORY In a impact test a specially prepared notched specimen is .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).TO DETERMINE IMPACT STRENGTH OF STEELBY CHARPY TEST AIM: To determined impact strength of steel. OBJECT: To determine the impact strength of steel by Charpy test APPARATUS: 1. Impact testing machine 2. A steel specimen 10 mm X 10mm X 55mm THEORY: An impact test signifies toughness of material that is ability of material toIn a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .

Izod Impact Test_manual - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document describes an Izod impact test to determine the impact resistance of a notched steel bar specimen. The test involves holding the specimen in a vice and allowing a pendulum to fall and break the specimen. The energy absorbed by the .(NIST), Materials Measurement Laboratory (MML), in Boulder, Colorado,by employees of . The Charpy impact test has been used worldwide since the late 1800s/ early 1900s [3,4] for characterizing the notch toughness of metals, and thereby their suitability for applications . This document provides the user’s manual for a software package .CHARPY IMPACT TESTING Charpy Impact Testing was first proposed around 1900 and has become a standart test in 1940’s. Main drive for implementation of impact testing testing in fabrication standards and material specifications came as a result of the large number of ship failures that occurred during World War II ( Liberty ships).Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),

Paper core Crush Tester solution

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.To find the impact resistance of mild steel. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected]

impact test report pdf

Charpy Impact Test - Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, . "The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a m.Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized.

OBJECT: To determine the impact strength of steel by Charpy impact test APPARATUS USED: 1) Impact testing machine 2) A steel specimen of 55 mm X 10mm X 10mm DIAGRAM: THEORY: An impact test signifies toughness of . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .CEAST 9000 Series | Pendulum Impact Systems - InstronLABORATORY MANUAL II Year B. Tech II- Semester MECHANICAL ENGINEERING STRENGTH OF MATERIALS LAB R18A0383. . Charpy impact test on metal specimen 10. Flexural strength of a beam 11. Fatigue Testing machine 12. Compressive Test on Cube 13. Brinell hardness test 14. Rockwell hardness test

To conduct Charpy V-notch impact test and determine the ductile-brittle transition temperature of steels. Equipment Coolants Standard Charpy V-Notched Test specimens Impact tester . Discussion (the questions will be answered in the lab report) 1. Give the estimated values of DBTT for your steel. Suggest 2 ways inCharpy Impact Testing, also known as the Charpy V-notch testing, helps determine a material’s toughness. In our comprehensive materials testing labs our experts perform this test in accordance with multiple standards including but not limited to the ASTM, ISO and EN.4. Izod and Charpy Tests on M.S, C.I Specimen. 5. Brinell, Rockwell and Vickers’s Hardness test. 6. Fatigue Test. COURSE OUTCOME: 1 Demonstrate the knowledge and skills to conduct and analyzing the results w.r.t. Hardness testing, Tensile testing, Shear, Compression, Bending test, Fracture testing, Fatigue testing and Impact testing.

Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .NextGen offers the advanced and automatic lzod and Charpy impact test for platic and rubber specimen testing based on Charpy test from 1J to 50J, and lzod test from 1J to 22J. . The new MULTISPEED tester is the ideal solution for Road testing laboratory. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible .The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.

Apparatus: Instron Charpy Impact Testing Machine Ice (to chill specimens) Oven ∣ Tongs Materials: Standard Charpy V-notch Specimens of 1045 steel References: Lab manual Van Vlack, Ch. 6 (reserve) Dieter, Ch. 7&14 (reserve) ASTM Standard E23 Background: Ductile and brittle failures of metals always happen during the service. Brittle fracture .Impact Test: Determining the impact strength of a given material using Charpy & IZOD tests. 3. Tension Tests using Universal Testing Machine: Tension test on the given specimens (at least 2 materials for comparison) and to plot the stress strain graphs. 4. Compression Tests using Universal Testing Machine: Compression test on theMECHANICAL BEHAVIOUR LABORATORY MSE 313: Laboratory Manual Instructor: Dr. Nilesh Prakash Gurao . Impact testing of materials (Charpy Impact test) (Lab-2) 4. Creep testing of materials (Lab-1) . Materials Testing Lab, Room No.116 (Extension), Ph.no.7959 GENERAL INSTRUCTIONS: 1. Each experiment will be carried out jointly by a group of students.

charpy impact test specimen size

charpy impact test sample dimensions

Resultado da 15 de dez. de 2020 · Video mostrando a melhor sensibilidade para emulador depois da atualização do free fire ! paibelud ff ஜ۩۞۩ஜ ılı.lıllılı.ıllı. DEIXA O L.

charpy impact test lab manual|charpy impact test calculations